As installation of traditional contiguous sheet pile wall, such as Z-sheet piles, is fairly well known, this article will discuss how to install a combined sheet pile wall.

Construction of a combined sheet piling wall is actually very simple and straightforward.

First, drive the the beams. The king piles can be (preferably) installed before the intermediate sheet piles. Hence, the construction of the wall can progress based on the earlier delivery of the beam sections. It is recommended to use a platform or a pontoon with a horizontal frame jig for setting and driving the beams for a combined wall. Minimum two point guidance is the most effective way to have control over the beam positioning and driving.

Secondly, install the sheet piling between the already installed king piles. The sheet piling can usually be installed with vibratory hammers, thus greatly reducing the total driving effort expended in the total length of wall installed.

Slight deviations of the beams (from the driving line) that are inherent to the installation process will be tolerated by the flexible joints of the intermediate sheet piling and connectors, thus avoiding much of the rework involved in walls that use only heavy sheets.

The behavior of the primary elements, whether beams or pipes, while driving into soil, is compact and stable. This advantage of the combined sheet piling over the contiguous wall in the setting/driving is another reason why combined sheet piling walls often represent the better, structurally superior retaining wall construction solution.

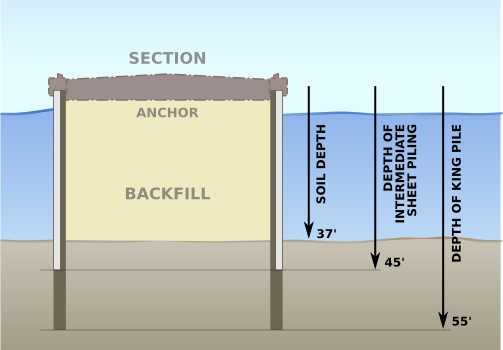

Combined sheet piling wall beam and pipe king piles are able to go deeper into dense soils than sheet piling sections of a contiguous wall — approximately 6.5 feet (2 meters) compared to 1.5 feet (0.5 meters). Quite simply, the intermediate sheet piling does not need to be installed to the same depth as the beams because they do not need to contribute to the moment capacity of the system at those depths. Hence, the sheets themselves, in a combined sheet piling wall, can be significantly shorter than the beams: in most cases, a 60% to 80% sheet-to-beam length ratio – which significantly reduces construction costs.

Here is an example of a typical combined sheet piling wall project to illustrate the above. This particular cofferdam project is in the Bahamas.

The fact that you only need to drive the beams and pipes to full depth and then simply set the intermediate sheets is an extremely important advantage of the combined sheet piling wall over heavier sheet piling from contiguous walls.

A combined sheet piling wall system has a typical sheet width of 6.33 feet (1.93 M) — two halves of each beam, two connectors, and two sheets. The usual sheet to beam ratio in a combined sheet piling wall system is around 75% sheet to 25% beam. Hence, you are likely to only encounter hard driving 25% of the length of a combined sheet piling wall versus 100% hard driving for a contiguous sheet pile wall.

In some cases where hard driving was experienced, it has been documented that up to 22 combined sheet piling wall systems have been driven in one 10-hour shift, amounting to well over 100 wall feet; in the same conditions, however, the same exact crew was only able to install about 1/3 of the wall feet with the heavy contiguous sheet piling that needed to be driven to full depth.

Enter your wall dimensions and the values below will adjust automatically.

| retaining wall type | construction days | total cost | cost per linear ft | cost per square ft |

|---|---|---|---|---|

| Steel Sheet Pile Wall | 47.69 | |||

| Soldier Pile and Lagging Wall | 90.45 | |||

| Concrete Modular Unit Gravity Wall | 76.18 | |||

| Mechanically Stabilized Earth Wall | 95.58 | |||

| Cast-In-Place Reinforced Concrete Wall | 136.09 | |||

| Slurry Wall | 210.60 |

Approximate cost and construction time for different wall types is based on 2009 RSMeans pricing for the US and extrapolated from the 2009 NASSPA Retaining Wall Comparison Technical Report,