Contrary to many misconceptions, steel sheet piling durability concerns are minimal for most applications. Use iSheetPile’s comparison tool to see just what we mean.

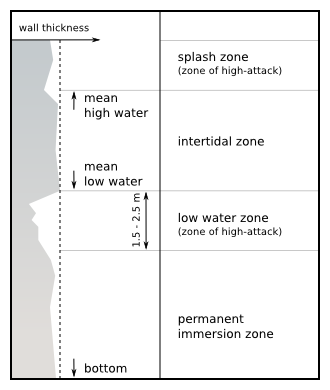

The following qualitative diagram of corrosion zones in salt water is taken from Figure R 35-1 from the Committee for Waterfront Structures Harbours and Waterways (EAU) 2004 handbook section 8.1.8.1.

Coating for steel projects (especially in non-salt water environments) is often unnecessary. Use iSheetPile’s corrosion simulation tools to determine if coating may even be needed.

Concrete retaining walls exposed to seawater often demonstrate noticeable and significant deterioration from the combined effects of the following chemical and physical processes: sulfate attack, leaching of calcium hydroxide (lime), erosion and abrasion from wave effects, alkali-aggregate expansion, salt crystallization from alternate wetting and drying, and effects due to freezing and thawing of concrete.

In addition to corrosion concerns, piles using concrete often have water tightness issues. As the US Army Corps of Engineers Design of Sheet Pile Walls Engineer Manual from 1994 states about concrete piles, “Past experience indicates this pile can induce settlement (due to its own weight) in soft foundation materials. In this case the watertightness of the wall will probably be lost.” (Section 2.4.4 Page 9).

Steel piling retaining walls are actually much more suited than concrete for use in marine and corrosive environments.

Even in the harshest marine environments, steel corrosion can be effectively minimized by simply taking into account the corrosion effect. This is done both when a given piling designation is chosen and/or by taking steps to protect piles or sheet piles against corrosion.

Committee for Waterfront Structures Harbours and Waterways (EAU) 2004 states in section 8.1.8.4: “According to available experience, coatings can delay the start of corrosion by more than 20 years.”

Nothing could be further from reality! iSheetPile deals with multiple steel sheet piling suppliers and can arrange for your order of steel piling to be at your job site within weeks.

The fact is: steel piling is not only stronger and more durable than concrete piling; it is cheaper, too.

The US Army Corps of Engineers Design of Sheet Pile Walls Engineer Manual from 1994 states on page 9 section 2-4b: “Concrete…has relatively high initial costs when compared to steel sheet piling. They [concrete piles] are more difficult to install than steel piling. Long-term field observations indicate that steel sheet piling provides a long service life when properly installed.”

See iSheetPile’s article Steel or Concrete for your Piling Project? for a further idea on whether steel or concrete may be best for your individual project.

Enter your wall dimensions and the values below will adjust automatically.

| retaining wall type | construction days | total cost | cost per linear ft | cost per square ft |

|---|---|---|---|---|

| Steel Sheet Pile Wall | 47.69 | |||

| Soldier Pile and Lagging Wall | 90.45 | |||

| Concrete Modular Unit Gravity Wall | 76.18 | |||

| Mechanically Stabilized Earth Wall | 95.58 | |||

| Cast-In-Place Reinforced Concrete Wall | 136.09 | |||

| Slurry Wall | 210.60 |

Approximate cost and construction time for different wall types is based on 2009 RSMeans pricing for the US and extrapolated from the 2009 NASSPA Retaining Wall Comparison Technical Report,