If you’re not familiar with corrosion-related calculations, you may want to read our article on Rust and Corrosion.

Just using A690 steel will not necessarily extend the life of your structure. Engineers who know this and argue for other solutions save their clients a lot of time and money; but wading through the marketing hype and pseudo-science isn’t easy. Here, we help you understand what the specifications and studies are all about and what they really mean.

If you are working in a marine environment, you should read below to understand the facts – especially that A690 does not necessarily increase the life of your steel sheet piling structure, and that it is not the most cost efficient choice, given its higher cost and lower availability.

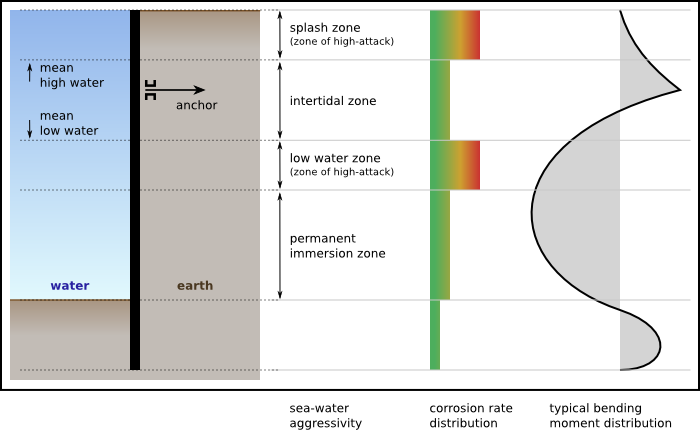

ASTM states that A690 is more corrosion-resistant than A36 and A328 in only the salt water splash zone.

The atmospheric corrosion resistance of [A690] is substantially better than that of ordinary carbon steels, with or without copper addition. The steel has also shown to have substantially greater resistance to seawater “Splash Zone” corrosion than ordinary carbon steel (Specifications A36/A36M and A328/A328M) where exposed to the washing action of rain and the drying action of the wind or sun, or both. Where the steel is not boldly exposed (like the low water zone or submerged zone,) the usual provisions for the protection of ordinary carbon steel should be considered.

The US Army Corps of Engineers in their REMR Technical Note EM-CR-1.6: The Use of A690 Mariner Steel Sheet Pilings states the following:

Unless there is a requirement for a high-yield-strength steel in construction in salt or brackish water, A328 steel sheet pilings with a protective coating in the splash and atmospheric zone should be the preferred choice in materials selection.

Note that A572 Grade 50 (like A690) is already a higher-grade material when compared to A328 (at 39 ksi).

ASTM A690 (or, “Mariner Steel”) was created and promoted by US Steel in the 1960s. At the time there was no grade of steel higher than A328 (39 ksi yield strength), and the US Steel sheet piling literature focuses on the fact that, as a stronger grade of steel, A690 (50 ksi yield strength) will be stronger longer than A328 once corrosion sets in (for any environment). [example]

But now, a half a century later, there are many grades of steel to choose from. The chart at right shows the yield strengths of several available grades. Note that A690, despite its high “model number,” is only middle-of-the-pack in strength.

When deciding on a material to use, keep in mind the following:

Even if A690 indisputably provided better splash zone protection than A572 Grade 50 (which has not been stated by ASTM), it will not provide any comparative benefit in the low water zone. So using A690 will most likely not extend the effective design life of your steel retaining wall because it has no advantage in the place it matters most (see bending moment distribution diagram from Eurocode BS EN 1993-95: 2007 BS EN 1993-95: 2007).

Enter your wall dimensions and the values below will adjust automatically.

| retaining wall type | construction days | total cost | cost per linear ft | cost per square ft |

|---|---|---|---|---|

| Steel Sheet Pile Wall | 47.69 | |||

| Soldier Pile and Lagging Wall | 90.45 | |||

| Concrete Modular Unit Gravity Wall | 76.18 | |||

| Mechanically Stabilized Earth Wall | 95.58 | |||

| Cast-In-Place Reinforced Concrete Wall | 136.09 | |||

| Slurry Wall | 210.60 |

Approximate cost and construction time for different wall types is based on 2009 RSMeans pricing for the US and extrapolated from the 2009 NASSPA Retaining Wall Comparison Technical Report,